LIGHTWEIGHT MOBILE TENT HALLS FOR SHIPYARDS

TENT HALL = STORAGE HALL = WHOLE YEAR FULLY FUNCTIONAL WAREHOUSE

How to increase a storage or production area in a rapid and cheap manner?

By erecting a tent hall, which does not require solid fundaments and is capable to meet every expectation for storage halls in terms of functionality. The storage halls are erected based on innovative constructions from anodized aluminum, which guarantees durability, safety (snow load of 25-250 kg/m²), ease of installation and diversity of usage.

Due to rapid installation (1 – 5 days) and durability (minimum of 10 years) the storage halls based on tent halls are a financially-attractive investment.

The tent halls fully meet the criteria of traditional buildings in terms of functionality and serve as a cost-effective alternative.

These extremly mobile shelters can be installed on tracks!

Possible applications of mobile tent halls for shipyards include:

- Covered docks

- Repair centers – providing shelter can greatly improve working conditions and maximize productivity.

- Production halls with low requirements in terms of thermal conditions: large-scale painting processes (paint booth), grinding of steel elements

- Winter storage of boats

- Warehouses – storage halls can be erected quickly and affordably, without time consuming building permits. Halls can be equipped with additional climate-control systems.

- Vehicle garage, heavy equipment storage

Permanent casing of the tent hall with non-flammable PVC with a weight of 670 – 900 g/m2 provides perfect protection for at least several years. The PVC casing may be easily fixed.

The transmission of light allows to save electrical energy during the day. Optional walls may be made from trapezoidal sheets or sandwich panels, which additionally reinforces the construction and improved the thermal isolation. A pneumatic roofing system increases the thermal isolation and facilitates the removal of snow.

Additional equipment may involve floors, entry gates, doors, lighting, ventilation systems, heating systems or air conditioning.

TENT HALLS FOR SHIPYARDS – PORTFOLIO

GET A QUOTE!MATERIALS

TENT HALLS WITH A CASING BASED ON TRAPEZOIDAL SHEETS

TENT HALLS WITH A CASING BASED ON SANDWICH PANELS (WITH FOAM OR STYROFOAM)

PVC-BASED ROOFING

PVC-BASED ROOFING WITH A HEADLINING

PNEUMATIC ROOFING SYSTEM

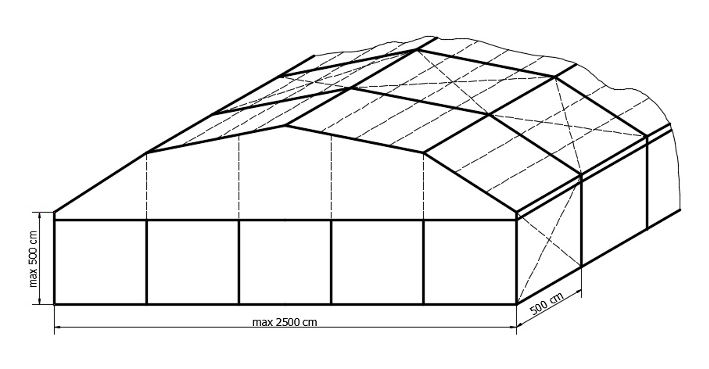

TENT HALLS – AVAILABLE SIZES

STORAGE HALLS „MADE-TO-MEASURE”

spread 4 -10m, height of the side wall 4.5m, segment spacing every 3m

CONSTRUCTION:

Main construction molding 94.2 x 47.3 x 2.4mm, pressed from 6005 AT6 aluminum alloy, the molding was anodized in accordance with QUALANOD: 2004

LINKERS:

Steel linkers mare from S355 alloy sections, with dimensions of 70mm x 40mm x 4mm, welded in accordance with the SLV DIN 18800-7 certificate, dip galvanized in accordance with the PN EN ISO 1461 standard,

ROOF COVER:

Tarpaulin PCV material made by the SATTLER company with a weight of 670 g/m2 with a non-flammability certificate issued by Institute of Construction Technique in Warsaw.

SIDE WALL CASTING:

PCV material

Dip galvanized and coated trapezoidal plate in the T-18 profile color, 0.5mm

Double layer disc filled with polyurethane foam, 60mm

spread 10 -15m, height of the side wall 5m, segment spacing every 5m

Main construction molding 150mm x 100mm x 3mm or 170mm x 880mm x 3mm, pressed from 6005 AT6 aluminum alloy, the molding was anodized in accordance with QUALANOD: 2004

LINKERS:

Steel linkers mare from S355 alloy sections, with dimensions of 70mm x 40mm x 4mm welded in accordance with the SLV DIN 18800-7 certificate, dip galvanized in accordance with the PN EN ISO 1461 standard,

ROOF COVER:

Tarpaulin PCV material made by the SATTLER company with a weight of 670 g/m2 with a non-flammability certificate issued by Institute of Construction Technique in Warsaw.

SIDE WALL CASTING:

PCV material

Dip galvanized and coated trapezoidal plate in the T-18 profile color, 0.5mm

Double layer disc filled with polyurethane foam, 60mm

spread 15 -25m. height of the side wall 6m, segment spacing every 5m

CONSTRUCTION:

Main construction molding 252 x 131 x 3mm or 307 x 116 x 3,7mm, pressed from 6005 AT6 aluminum alloy, the molding was anodized in accordance with QUALANOD: 2004

LINKERS:

Steel linkers mare from S355 alloy sections, with dimensions of 70mm x 40mm x 4mm welded in accordance with the SLV DIN 18800-7 certificate, dip galvanized in accordance with the PN EN ISO 1461 standard,

ROOF COVER:

Tarpaulin PCV material made by the SATTLER company with a weight of 670 g/m2 with a non-flammability certificate issued by Institute of Construction Technique in Warsaw.

SIDE WALL CASTING:

PCV material

Dip galvanized and coated trapezoidal plate in the T-18 profile color, 0.5mm

Double layer disc filled with polyurethane foam, 60mm

spread 25 – 35m, height of the side wall 6m, segment spacing every 5m

CONSTRUCTION:

Main construction molding 252 x 131 x 3 mm or 307 x 116 x 3,7 mm, pressed from 6005 AT6 aluminum alloy, the molding was anodized in accordance with QUALANOD: 2004

LINKERS:

Steel linkers mare from S355 alloy sections, with dimensions of 70mm x 40mm x 4mm welded in accordance with the SLV DIN 18800-7 certificate, dip galvanized in accordance with the PN EN ISO 1461 standard,

ROOF COVER:

Tarpaulin PCV material made by the SATTLER company with a weight of 670 g/m2 with a non-flammability certificate issued by Institute of Construction Technique in Warsaw.

SIDE WALL CASTING:

PCV material

Dip galvanized and coated trapezoidal plate in the T-18 profile color, 0.5mm

Double layer disc filled with polyurethane foam, 60mm

spread 35 – 50m, height of the side wall 4,5m, segment spacing every 5m

Main construction molding 304 x 136 x 6/10mm, pressed from 6005 AT6 aluminum alloy, the molding was anodized in accordance with QUALANOD: 2004

LINKERS:

Steel linkers mare from S355 alloy sections, with dimensions of 70mm x 40mm x 4mm welded in accordance with the SLV DIN 18800-7 certificate, dip galvanized in accordance with the PN EN ISO 1461 standard,

ROOF COVER:

Tarpaulin PCV material made by the SATTLER company with a weight of 670 g/m2 with a non-flammability certificate issued by Institute of Construction Technique in Warsaw.

SIDE WALL CASTING:

PCV material

Dip galvanized and coated trapezoidal plate in the T-18 profile color, 0.5mm

Double layer disc filled with polyurethane foam, 60mm

spread 15 – 30m, height of the side wall 5m, segment spacing every 2,5 – 5m

Main construction molding compatible with GAMMA 1, GAMMA 2, or DELTA pressed from 6005 AT6 aluminum alloy, the molding was anodized in accordance with QUALANOD: 2004

LINKERS:

Steel linkers mare from S355 alloy sections, with dimensions of 70mm x 40mm x 4mm welded in accordance with the SLV DIN 18800-7 certificate, dip galvanized in accordance with the PN EN ISO 1461 standard,

ROOF COVER:

Tarpaulin PCV material made by the SATTLER company with a weight of 670 g/m2 with a non-flammability certificate issued by Institute of Construction Technique in Warsaw.

SIDE WALL CASTING:

PCV material

Dip galvanized and coated trapezoidal plate in the T-18 profile color, 0.5mm

Double layer disc filled with polyurethane foam, 60mm

Quality, stability of construction, safety

Attention to details, proven design solutions, guaranteed durability and stability of construction of the tent hall – without any support and internal lines – allows to use the full volume of the hall.

pneumatic roofing system increases the thermal isolation of the hall and facilitates the removal of snow.

FUNCTIONALITY – VERSATILITY OF USE

STORAGE HALLS – LOGISTIC CENTRES

INDUSTRIAL HALLS

PAINTSHOPS

CARWASH

WASTE SORTING PLANTS

PIGPENS – COWSHEDS – HEN HOUSES – CHAMPIGNON STORING HALLS – FRUIT SORTING PLANTS

STABLES – HORSE RIDING FACILITIES

SPORT HALLS – TENNIS COURTS – ICE RINKS

building, industry, logistics, automotives, trade, agriculture

WHY TENT HALLS?

- COST-EFFECTIVE ALTERNATIVE TO HEAVY BUILDINGS

- MOBILITY, FAST INSTALLATION AND REMOVAL (1 TO 2 DAYS)

- DURABILITY – MINIMUM 10 years

- RESISTANCE TO EXTREME WEATHER CONDITIONS – WIND, SNOW, HAIL, RAIN

- TAILORED SOLUTIONS (INSULATED WALL PANELS, ENTRANCE GATE, WINDOWS AND DOORS, PUMPED ROOF)

We were trusted by:

WE WORK GLOBALLY

The quality of our tent halls is appreciated by clients all over the world.

SPITSBERGEN, OMAN, NORWAY, SAUDI ARABIA, RUSSIA, GREECE, FRANCE, GERMANY, GREAT BRITAN, SPAIN, HOLLAND, ITALY

THE QUALITY OF OUR PRODUCTS IS ATTESTED BY THE FOLLOWING STANDARDS AND CERTIFICATES:

POL-PLAN Sp. z o.o.

ul. Wrocławska 42/44, 62-060 Stęszew / Zamysłowo

REGISTERED CAPITAL: 5 800 000,- PLN – paid in full